One of the most odd-looking tools we use in the workshop is the poising tool.

This little apparatus is one of the tools we use to test whether a watch's balance wheel is properly poised. But how does it work, and what does it mean for a balance wheel to be properly poised?

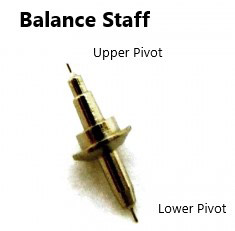

Let's start with the balance wheel itself. The balance wheel can be thought of as the beating heart of a mechanical watch, serving to regulate the flow of power throughout the gear train so that the watch keeps proper time. For it to do so, the balance wheel must be perfectly balanced; which is to say that the weight must be equally distributed around the circumference of the wheel. As well, the upper and lower pivots must be perfectly straight and have exactly the same diameter, otherwise the balance would tend to tilt in a certain direction. The poising tool is but one of the tools we use to check whether this is so.

The tool must first be placed on a flat surface and then, using the adjustable legs, adjusted until it’s level. When the tool is perfectly level, the little water bubble in the red enclosure will float directly in the centre. The ruby jaws must then be thoroughly cleaned and inspected, as even a minute speck of dust can cause a false-positive when testing. The balance wheel with spring removed is then placed between the chucks with the tips of the upper and lower pivots resting on the ruby.

How this is fixed depends on the type of balance wheel (whether it has timing screws or not), and may require the removal of material. As you can imagine, for such a small part the amount of material that would need to be removed to correct an imbalance would be minuscule, and there is another watchmaking tool made specifically for this purpose!

(Left: A balance wheel with timing screws, which can be adjusted to change the balance of weight. Right: Note the small circular indents around the outer rim where material has been removed.)

The symptoms of bent pivots are much the same, but can be diagnosed as such if the wheel appears to wobble as it’s rotated. Fixing bent pivots at this scale is, well, difficult, and sometimes not possible at all…or simply not worth the effort. A new balance staff is often the quickest and best solution.

The replacement of broken balance staffs was once a common watchmakers job, especially during the pocket watch era, but since the invention of shock absorbers in modern timepieces (around 1920s) the need for balance staff replacement - and consequently the posing tool - has been significantly reduced. Furthermore, watchmakers have now developed alternative methods for checking the poise of a balance wheel (known as dynamic poising, whereas the use of the poising tool is referred to as static poising), but the poising tool still has a place in almost every workshop as a quick and easy-to-use diagnostic device. We’ve also found a very handy use for the tool in another aspect of watchmaking: Not just for the repair of existing parts, but in the manufacturing of them in the first place, which is what we’re doing with our rebelde watches.

When a new pinion is turned and a gear freshly hobbed, you’re faced with many of the same problems: Are the sides of the upper and lower pivots perfectly parallel with each other? Is the weight distribution of the gear equal?

Of course, our first test is to simply measure the new parts and compare them with expected dimensions, but, as you know, looks can be deceiving, and the use of the poising tool in this regard has served as an effective litmus test to check for the overall quality of the new part.

0 Response to "Watchmaker’s Poising Tool by Tyler"

Post a Comment